It inspired the 2010 Nobel Prize in Physics.

It’s the best thermal conductor we know of.

It’s a crystal stiffer than diamond, but able to stretch by 20% of its length, and can carry a current density one million times higher than copper.

It could even be the future of high-speed internet.

But, sure, you’ve probably never heard of it.

It’s called graphene: a single plane of carbon atoms closely related to graphite, which itself is composed of graphene layers one on top of the other.

Why we heart graphene

If graphite is a skyscraper, graphene represents each storey within that skyscraper.

Five levels of graphene or more gives you graphite, but at just one or two layers, our wonder material starts to get interesting.

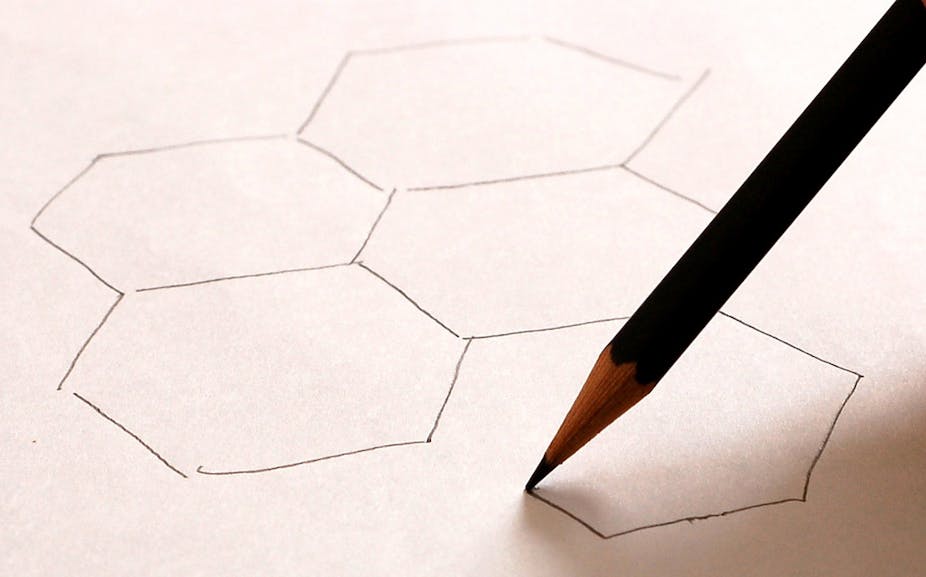

Thought to be two-dimensional in nature, graphene is essentially chicken wire on a nanoscale, with hexagons of carbon atoms sharing edges, and atoms resulting in a slightly wavy layer only one atom thick.

That’s on the angstrom scale, one ten-billionth of a metre.

Here’s one we made earlier

For such an amazing material, you’d think the production process would be complex, but it all started with a pencil and some sticky tape.

In 2004, professors Andre Geim and Konstantin Novoselov from Manchester University managed to isolate a single layer of graphene by continually sticking and unpeeling tape to a crystal of graphite, just like those found in pencil lead.

And so a major boom into graphene research was born.

Graphene is now being produced on a larger scale using three predominant methods, all of which have their own limitations:

1) Chemical vapour deposition involves depositing carbon as graphene layers onto copper or nickel from methane or acetylene gas.

2) Directly growing graphene from a carbon source on a metal catalyst using a high temperature furnace.

3) Chemically reducing graphene oxide, an altered form of graphene, to make layers without restacking or formaing graphite, a problem that plagues the above methods.

Graphene hearts you

With growing development and production, the chance of coming into contact with items containing or consisting of graphene-based components is growing ever more likely.

Graphene’s incredible strength and low weight allows it to be used in a composite with polymers for windturbines and aircraft components.

The incredible lack of electron resistance means it’s often used as a transistor, an electronic switch and amplifier at frequencies that would be impossible with current state-of-the-art silicon.

Next year, Samsung will release its first phone with a graphene screen coupled with organic light emitting diode (OLED) technology.

This would be cheaper than current materials, and would use minimal energy, eliminating metallic components from the screen and thereby increasing recyclability.

Graphene’s optical clarity can also be utilised in solar cell applications, absorbing just 2.3% of the light that hits it, less than one quarter of the light absorbed by the currently used indium tin oxide.

Graphene is also extremely elastic for a crystal, perfect for those delicate touch screens that always seem to break.

It can also outperform the capacity of traditional batteries.

The iPhone’s battery, for example, could have the same electrical storage it currently does, but be recharged in seconds. Imagine that! I mean, just imagine …

Graphene has set record after record, with 3,000 papers published on it last year alone.

There’s no doubt this wonder-stuff will soon be used in almost every aspect of your home, work and transport.

World, it’s time to start loving graphene.